More than any other factor, it was the rapid decline in the cost of solar energy that inspired me to start the Freeing Energy Project. The cost per watt of solar panels has dropped more than 100-times in the last few decades and is now cost-competitive with every other form of electricity generation, including coal, natural gas, nuclear, and even wind. Of course, this incredible decrease in cost begs the obvious follow-on question: can the price of solar possibly keep going down?

If you want to understand the costs underlying solar power and the trends driving it downward, Dr. Markus Fischer is one of the world’s foremost experts on the topic. He is VP of R&D Operation at Hanwha Q CELLS, one of the world’s largest solar manufacturers, with the largest output of any company outside of China. As a member of the steering committee of the ITRPV (International Technology Roadmap for Photovoltaic), he is also the primary author of this definitive report that tracks all the technologies and costs behind solar cells and panels. I recently had the opportunity to visit him at his offices in Thalheim, Germany and ask him about the trends behind the astonishing decline in the cost of solar power.

How has the cost of solar declined so much more than any other kind of energy generation?

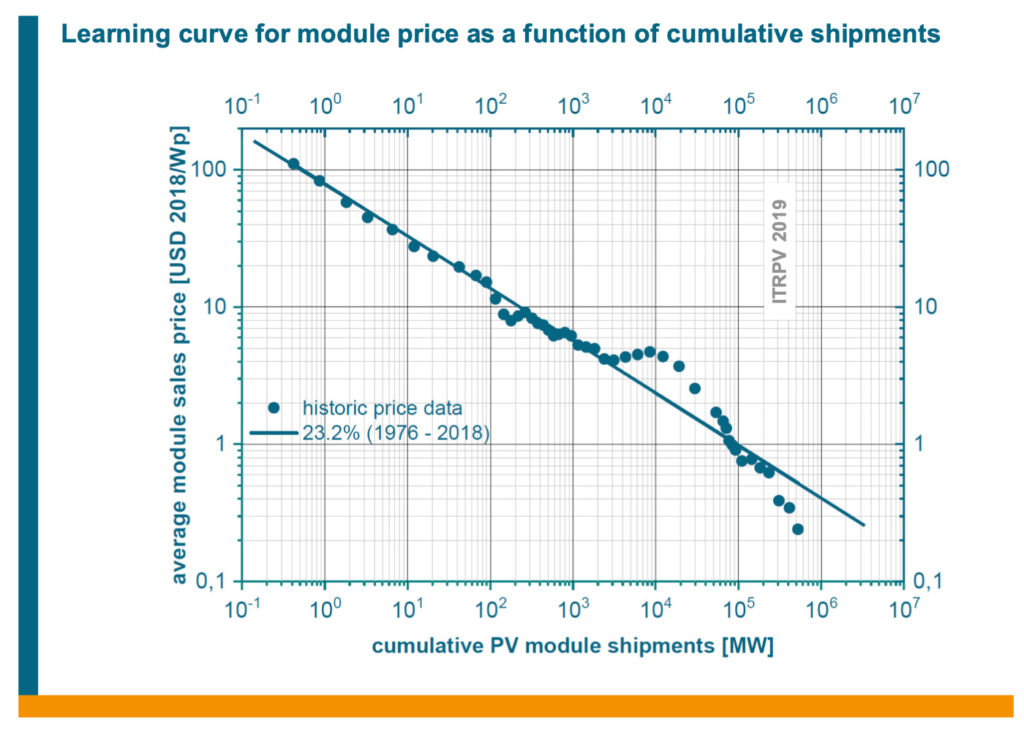

“Economies of scale are the backbone of the PV’s big success,” explains Markus. Each new cell or panel manufactured, along with every new manufacturing plant built, increases the “learning curve” In other words, the more you make, the more you learn. The small, inexpensive nature of solar cells and panels make it possible to experiment, pilot, and learn at a very rapid rate compared to other energy technologies. These learnings mean manufacturing can be fine-tuned, automated, and inexpensively grown to huge scales.

The learning curve effect and its impact on the declining price of solar is clearly visualized in the very first graph in the 2019 ITRPV report.

My perspective is that solar is the only mainstream energy generation technology that can be mass-produced in highly-automated factories. Consider that only 700 nuclear power plants have ever been built since the industry began but more than 20 billion solar cells were made in 2018 alone. Even gas turbines and wind turbines are made in the thousands and tens of thousands, not even close to the scale of solar.

GET MONTHLY NEWS & ANALYSIS

Unsubscribe anytime. We will never sell your email or spam you.

What areas will be most important in the future cost declines in solar?

Overall, the greatest improvements in cost come from simply doing more of what is already working well. Markus told me several of the processes and technologies that lower costs (or increase efficiency) are now considered mature enough to be widely adopted. He said factories across the world are upgrading to them as quickly as they can. While there are dozens of improvements, he highlighted three:

- Shift from BSF (Back Surface Field) cells to PERC cells (Passivated Emitter Rear Cell). This decade-old technology allows more electrons to be captured, improving the efficiency of a cell. Implementing it requires factory upgrades but the industry has decided it’s worth the cost.

- Fast roll-out of Diamond wire sawing that replaced the slurry based sawing technology enabling a significant reduction of Si losses during the wafer cutting process.

- Shift from multi-crystalline to mono-crystalline wafers. While the industry started with multi-crystalline silicon, companies have greatly improved making the purer and more efficient mono-crystalline cells. The cost difference is now so small that using mono is quickly overtaking multi.

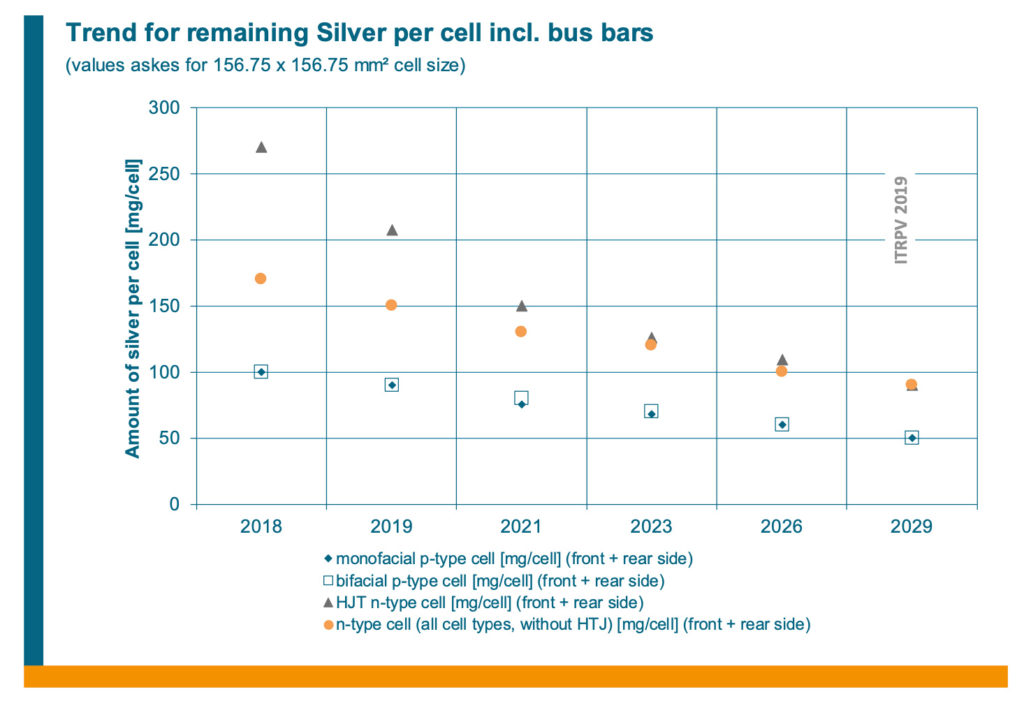

- Reduction of remaining Silver at the finished cell by continuous improvements to screen printing technology.

In terms of materials, Dr. Markus said, “the thickness of the silicon wafer used to be the number one factor in lowering the cost but now it’s silver.” Using a technique surprisingly similar to screen printing a t-shirt, silver is laid down on a silicon wafer in visible vertical “busbars” and nearly invisible horizontal “fingers.” Together, this silver gathers up the electrons generated by light photons hitting the silicon and delivering them into the panels and circuits that ultimately connect to our homes and grids. For its weight and size, silver is the most expensive non-silicon part of a solar panel. Discussing the specific numbers, he told me, “today’s cells use about 90 mg of silver but we expect this to drop down to 50 mg by 2029” (see figure 8a in the 2019 edition of ITRPV). Even today’s 90 mg is a huge drop from the 400 mg used per cell as recently as 2009.

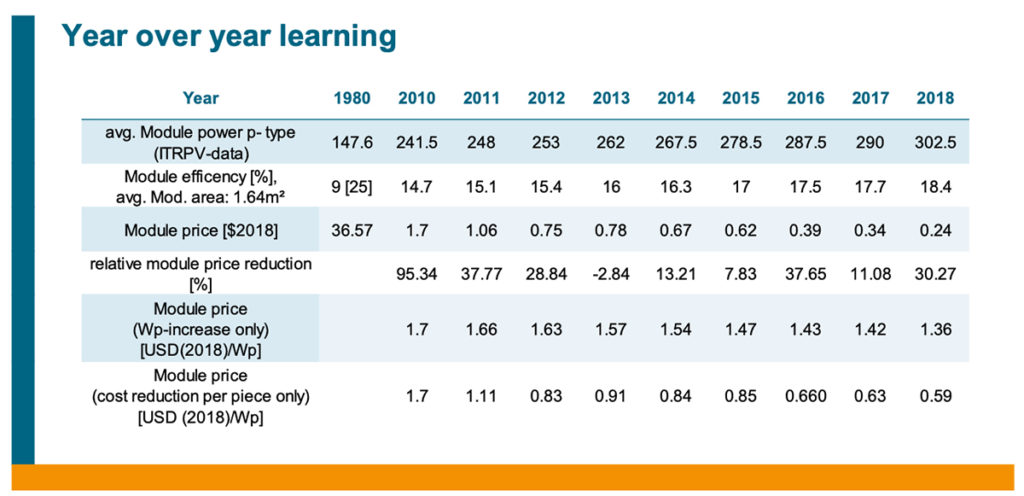

The Freeing Energy Perspective

The first table in the 2019 ITRPV report sums up this story well by revealing just how far the cost of solar has declined — from $36 per watt in 1980 to $0.24 in 2018, 150-times cheaper. No other mainstream energy source has seen similar declines and only solar is expected to see continued aggressive declines in the future. Nearly every other kind of power generation requires giant machines that have relied on increasing their size and complexity to lower their costs. The secret of solar is as simple as it is unassuming — solar cells and panels are small. We make them by the billions. It’s what I call “economies of volume.”

The best news of all is that continuing to lower the cost of solar doesn’t require some kind of radical scientific breakthrough. Continued declines will be a natural result of thousands of scientists and engineers across the world making countless improvements to solar materials and factories. To highlight this point, Dr. Fischer pointed me towards a paper by Winfried Hoffmann and Axel Metz titled, “Modules at a Price of 10 $ct/Wp – Dream or Reality?” that analyzes 22 different technologies and materials that are used to manufacture solar. It extrapolates the cost and efficiency trends on each one of them. Virtually every one is trending towards cheaper, more efficient panels, including thinner cells, reduced silver, longer lifetimes, less waste, faster factories, and less electricity in factories. Together these trends tell an exciting story about solar’s ongoing cost declines. To reach 10 cents per watt and actual electricity prices around 1 cent per kilowatt hour, we just need to keep installing more solar and building more factories. Depending on how fast we ramp, the Hoffmann and Metz analysis shows we could reach 10 cents per watt in two or three decades, easily making this the cheapest form of energy ever created.

Additional reading

The full ITRPV report is available for free — download here.

One Response

Awesome post! Thanks for sharing the knowledge and keep up the good work.