There is a revolution in clean local energy coming fast and it’s a good bet that you’ll never even see it. Building Integrated Photovoltaics, or BIPV, ditches the notion of black rectangular panels and instead transforms your house or building into a solar power generator.

Listen in as Laura Sartore, the CEO of Italian module equipment firm, Ecoprogetti, shares how her firm is blending engineering, aesthetics, and automation for BIPV. Her firm is revolutionizing local energy, not just by making solar power beautiful and affordable at the same time, but also making equipment that is designed to let companies manufacture solar panels in their own regions and countries everywhere in the world.

Learn more about Ecoprogetti at their website: https://ecoprogetti.com

Listen to this podcast and others in our series on these platforms:

A Tour of Ecoprogetti

The world of building integrated photovoltaics (BIPV)

Transcript

Bill:

When we look out a couple of years, the notion of a solar panel being a flat black rectangle is just going to be history. The future is colorful, it’s aesthetic, it’s beautiful and we’re going to learn how to do it. So I had the great privilege of meeting today’s guest at her headquarters in Padua, Italy a few months ago. She spent the afternoon with me. I explained this amazing business she’s building and showed us the products they’re creating. She’s joining us here today to share this story with all of us and kind of get us as excited as she’s gotten me about the future of solar that’s going to be beautiful. So I’m really excited to welcome Laura Sartori, the CEO of the globally respected solar module maker, Ecoprogetti. So Laura, welcome today.

Laura:

Thank you very much, Bill. Thank you very much for your kind words and welcome to everybody, to the listeners.

Bill:

I’ve been incredibly fortunate to have spent some time with you both preparing for today’s podcast and also all that time we spent at your headquarters in Italy. Through that, I’ve learned that you have one of the more interesting and kind of cool stories about how you got here and what your company does. So as we like to do with the Freeing Energy podcast, want to start off a little bit about who you are. You grew up in a solar family. You’ve kind of thought about solar before, probably, most people in the world. So tell us about what it was like and how you got exposed to the world of solar early on.

Laura:

Thank you very much. First of all, again, thank you for visiting us and for giving me the opportunity and to our company to explain a little bit about how we work and what we look like.

I do come from a solar family. My father started very young his career in the solar, and as a CEO and a managing director initially. He worked at the very beginning as a managing director in the semiconductor industry, but he switched very early and after from 1986, he started more actively to be involved in the solar. So he has been practically the same time as my age in this industry.

Solar was initially only an extreme technology, used for space applications, for R&D. At that time, I believe he saw the potential of this renewable energy and he never let it go. So he founded his first company in 1994. From that time, our only activity is solar, and renewable energy. He started when solar was unknown to everybody. When my father started in the solar, there was no equipment. Everything was made manually.

So being real Italian, how do you make manually the first PV panel? We started, and he always told me that the first PV panel was cooked and baked inside the oven of the kitchen, basically. So it was really strange. But at that time, there were no machines, there was no equipment to particularly manufacture the PV panels. And so when he started, everything was like a trial. So he always tells this story that he baked the first model inside a kitchen oven, which is very strange but true.

Bill:

And you told me something that made me chuckle, what, when you were in school and the kids would all go around and the teacher would say, “So what does your father do or what do your parents do for a living?” What was that?

Laura:

Yeah. I mean, it was really challenging at the beginning because, oh yeah, the main topic in primary school was like, which is your father’s job? Or what is your father doing? And when you answer, “Yeah, you know, he’s making solar panels, renewable energy,” typically, the teacher was looking at you like, “Oh, poor girl. Take a candy. You must be starving because your father doesn’t have a job.” So it’s totally crazy. But this is how was the perception at that time of the people towards the solar panels.

Bill:

You learned early on how hard it is to pave a different path than what everybody else is doing, and it’s clearly worked well for you because you’re once again pushing the industry in ways that others don’t necessarily see just yet. But I’m convinced, as many are, that you’re taking your company in an amazing direction.

So let’s talk about how you ended up at Ecoprogetti, because you obviously grew up in a family that was focused on solar, but you didn’t jump right into it. How did you end up there at the company ultimately?

Laura:

I started initially did my studies both in Italy and Germany in economics, finance, and law. And actually, I found very early, my first job. It was in an audit company, one of the big four PWC, PricewaterhouseCoopers. And over there, I was involved in the auditing, financial advisory and I was working primally with big companies, stock companies, insurance companies, banks, financial institutions, which was totally far away from the renewable concepts.

After almost five years of this life, which was really exciting and enriching for my business experience and background, I felt I wanted to be part of not only auditing or controlling other companies and what other company are doing, but also I wanted to make a difference and be part of a company that was actively doing something and not something general, something good. So our family company at that time was growing a lot. And at the time I joined in 2015, it was really a booming year for Ecoprogetti and also for the solar industry.

Probably that year was one of the years with the biggest results and expansion of our industry — this is when I joined. So after five years of numbers and controlling and traveling mostly with a big stock company, I shift completely my life and I joined our family company much smaller at the time. There is a joke, Bill, that we always say in this industry, is that when you’re jumping to solar, you feel that you can never go out, basically, because you are feeling that you really do something that you like and that it matters for the whole environment and for the Earth.

Bill:

Thank you for being in solar. And that’s a great story of how you got there. I will forever recall your walking me through the building after building at your facility and these amazing machines, which we’ll talk about briefly. What you do is really not visible to a lot of people. We see the panels, we understand the cells, but making both of these is incredibly hard and it’s also very different. The part that Ecoprogetti focuses on is making the panels, the modules as the industry calls them.

Laura:

Correct.

Bill:

So a lot of people have heard of the companies that ultimately make panels like QCELLS and Jinko and some of the large solar manufacturers. But ultimately, they’re making their factories with machines that they themselves didn’t make. They’re getting the machines from other companies like yours to build their factories. Now I love the fact that you’re in Italy because Italy has such an amazing tradition of making beautiful, sophisticated things, textiles and glass and now solar panels. So tell us a little bit about Ecoprogetti and what do you guys make?

Laura:

Ecoprogetti means ecological projects. This is the meaning in Italian of our name, our company name. And we are an automation company. So we do design, manufacture, and there lies all the machines, all the turnkey solution to produce the PV module locally. So our company makes the machine, the complete production line, which as you said are behind these big giants that produce solar panels. Solar panels are the final ingredients to produce this electricity, definitely. But we are located here in Italy where there is a huge district, and we are in the Silicon Valley of the solar, which is close to Venice.

There are really many companies that make automation, automation, as you said, for textile, glass, marble, a lot of different industries. And here is where we sit. So Ecoprogetti born inside the industry district of machine manufacturing, and we specialize only in solar machines. Our mission definitely is to be able to allow all the people from any part of the world to start new production of photovoltaic panels locally.

Typically, we see these big giants that manufacture panels, but this doesn’t mean that every local community can also be able to manufacture the PV panels. Electricity is required everywhere, so this is the starting point. I would say we are at the beginning of the solar supply chain. Since in the beginning, you have to be able to produce the final product.

And how we work. In Ecoprogetti, we work more like tailors, I would say. So we weave generally for our customers, the machines that they require to produce the PV panels, high quality, customized and very flexible, so adjustable to change the various requirement of the market.

Bill:

I’ve understood conceptually what you guys do, but since I’ve visited your factory, I’ve come back and told many of my friends about the incredible tour we had. I mean, some of these machines that you guys make, they’re the size of buses. And the part that really fascinates me about the machines that you make is that on one hand, these panels, the normal-sized ones, you make all kinds of panels, but you also make normal panels, these things are 30 or 40 pounds. Yet the cells that go inside of them, if you lift them up wrong and a breeze blows, they crack. So you’ve got this incredible synergy between heavy industrial equipment and incredibly sensitive material handling. And so to me, it’s kind of like the cross between a neurosurgeon and a bulldozer comes together to make these machines. So for folks that don’t understand the industry, what do these machines actually do? And why is automation so important?

Laura:

So the starting point for PV panel, as you mentioned before, is the solar cell. This is definitely the base unit which is assembled together in a matrix to realize the solar panel, the final solar panel. The solar cell is really thin, so required a type of automation to handle that is really micro-mechanic, micro-electrical, and have definitely a lot of different features than the must heavily big automation which you mentioned that you have seen in our factory.

Basically, along all the production line, there are really different equipment and machines that have different factions. Stringers connect the solar cells together. The laminator, for example, is the machine, which laminates and that cures and that cooks the PV panel. The other main machines which we are proud to manufacture is the testing equipment: sun simulators, EL testers. These are all quality equipment for the control of the final electrical values, power output, and also the visual aesthetic of the PV panels to guarantee that all the PV panels are produced with [inaudible 00:12:27] of the highest quality.

Bill:

That’s a really great overview. Thank you. Let’s talk a little bit about Italy and how solar fits into Italy because obviously one of the reasons that you’re there is Europe and Italy specifically are incredibly excited and committed to solar energy. Most of our listeners are from the US and they’re probably very familiar with US policy and approach and culture around solar, but it’s… Italy really, really impressed me. Then, nothing impressed me more than hearing it through your words about how does Italy think about solar and why is it that as I was driving to your fantastic offices, that every single building I saw seemed to have some kind of solar panel on it, at least the more modern-looking buildings. I didn’t see any solar on the older looking buildings, but the modern buildings all looked like they had solar. What’s going on in Italy?

Laura:

Thank you for asking. And really, thank you for the nice words. You know, our country is typically the country only for tourism, but everybody remembers the postcard of Italy with the red roof and the red colors of the houses. We have started since few years without really big and massive program integration of the solar in each and every house. This is something which is pretty strange and unusual maybe for new markets. But in all of Europe and in Italy mostly where we have a lot of sun, as you know, the government made really huge step forward for the integration of the solar. Typically, here in Italy, we have in the Italian market, the shifting to the solar could not be without an aesthetical eye also on the houses.

Typically, as you know from our specific cultural and building industry, we have a lot of red roofs. Heritage protection required in some areas in the whole of Italy, and in many parts of Europe, the roofs are red. So can you think about Venice or Rome or Paris covered with solar panels? This is kind of strange.

So this drove the industry to find new solutions to integrate the PV panels inside the roofs in the houses and in all the heritage buildings, which we have in Italy. Many historical cities have restrictions on the standard blue PV panels on the roof. So even though we have strong government support and in Italy, I don’t know if I mentioned, but there is a law where every new house… and this law, it’s up from 2016, so it’s almost five years… that every newly built house or refurbished house needs to have solar panels installed inside the roof. One kilowatt installment for every new house which is up in the field. It’s quite tough for everybody who wants to build up a new house, but it’s helping a lot the industry get inside daily life. So if you want to have a new house, you need to put a solar panel on top.

Bill:

So what do you do if you’ve got one of these red roofs and how do you stick one of those big old black rectangles on top of a red roof?

Laura:

In Europe, there is a big, big development for alternative models, which we call BIPV, building-integrated photovoltaics. These panels are aesthetically different from a standard panel, for example, in color, in thickness, in distance. You can see easily a red panel which looks exactly like a traditional red tile, installed in the houses for the heritage protection, or they can be white, exactly like the white facade of the buildings, or they can be colored, for example, for banks or typical tall buildings and fancy facades.

Bill:

So this is a really, really big deal. I want to make sure that everyone got that. So in Italy and across Europe, it is required that every new home or every refurbished home has to have solar on it, which is fantastic. And in the US, we have that in California, and only California at the moment, but across Italy and Europe, that’s the case.

But as you pointed out, there’s a lot of buildings that are heritage, beautiful buildings, and you don’t want these black or blue rectangles up there. So just to be clear, you’re saying that there’s a lot of buildings that have solar panels and those solar panels are red?

Laura:

Red, terracotta, all these type of-

Bill:

And white solar panels, you said, white solar panels?

Laura:

And white solar panel, yeah, definitely. White, black. This is becoming the market standard, not only for Italy, but we do see this is an increasing trend in the solar PV industry. So solar is not only an add-on on the roof, but it’s becoming colored and part of the roof where you want to install it.

Bill:

This is so big to me because you think about the effort of taking solar panels on top of an existing roof. You have to build the roof. I have to put the shingles if it’s a typical American shingled house, and then you have to go back up on the roof and put the solar panels on top of the shingles. I think a lot of people are familiar with Tesla’s solar shingles. Most people haven’t seen them. They don’t really understand what it means, but the basic economics is if you just start by putting those on your roof, it’s actually cheaper than putting normal old-style shingles and solar on top of it.

And this is just the beginning because very few people have those panels, those shingles, very few people outside of Europe have those red, terracotta panels, but as we make more and more of those, the volumes go up, the prices will come down and suddenly we’ll find that they’re going to be competitive with everything.

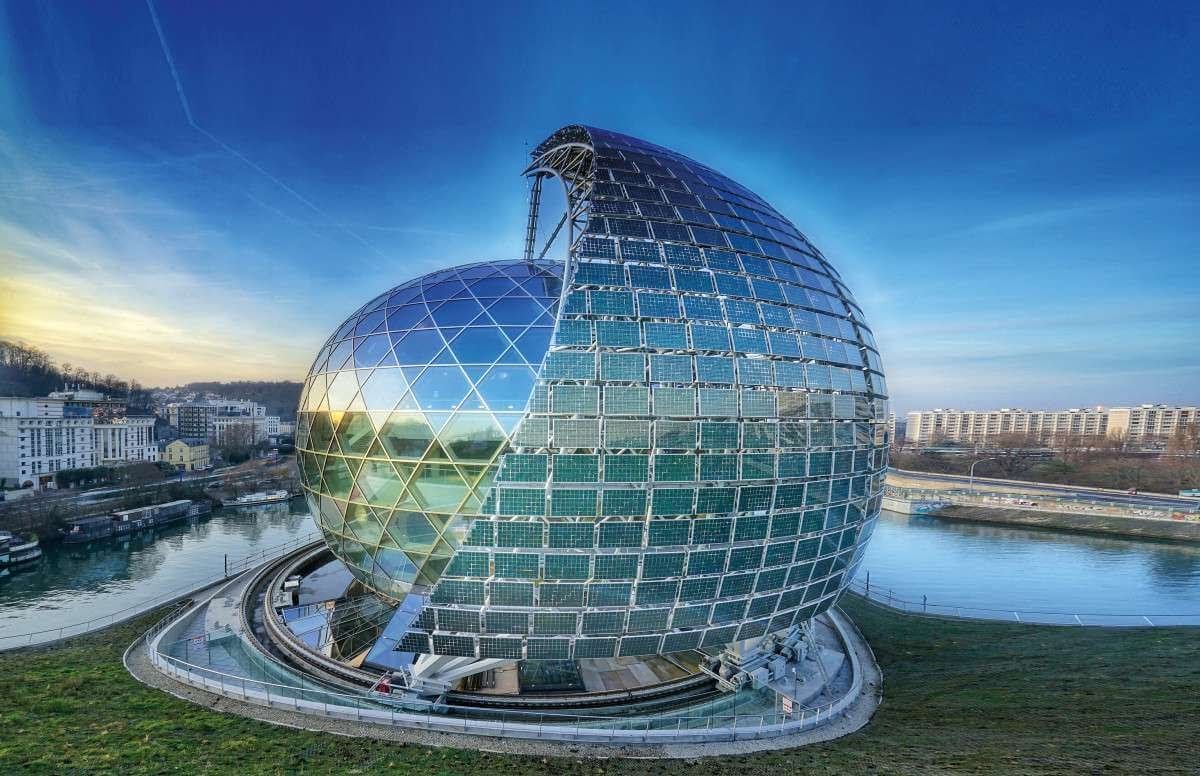

This is why I’m so excited what Ecoprogetti and you are doing because you’re helping make the volume, make the machines, automate them, lower the prices. You’re putting your money where your mouth is as we like to say because as I drove up to your building, there’s just a beautiful Italian landscape like you see in postcards and just trees and plants and farms and these beautiful homes. And then off in the distance is this set of… this cluster of buildings, industrial-looking buildings. They’re tall and not a lot of windows, but there’s one building at the corner, and the driver’s like, “That’s Ecoprogetti.” It had this beautiful curved facade of solar panels, I guess. So tell us about what your building is doing on the outside. What’s that look that you’ve created?

Laura:

So Bill, when you saw our building for the first time, I think you realized that we have a curved facade in front, which is not just a facade, they are all PV panels. So in front of our building, we do have shingle covering of lumped tiles, which are the facade of the building. They work like cartons in front of our offices.

Laura:

This type of design was done by our founder, so my father. You know he is a designer, an inventor. So at the very beginning, he drove his own building and he made this kind of facade in order to show the models outside and also to have electricity and to save electricity inside the offices.

Bill:

How does it save electricity?

Laura:

These panels are not only producing electricity but they are even acting as a curtain, as I said, in front of our building. So they basically reduce the light which comes inside from the windows, and they reduce the consumption of the AC during the summertime.

Bill:

Got it. It just looks really cool. I think of all the podcasts I’ve ever done, this one, when I put it on our site, is going to have more photographs of your facilities, of the company’s products that people have used your technology to make their own buildings and products with. So the outside was cool and it’s aesthetic and it’s gorgeous and you haven’t seen… most of us haven’t seen many buildings like that.

But the other part was we’re walking through your building and it’s well-lit despite having the facade and it’s this beautiful building. But in the center of your building, there’s a set of stairs. You immediately know something is a little strange because the stairs have… They’re lit by sunlight. I remember you saying, “Hey, do you want to see the roof?” And I was like, “Okay.”

So we walked up this gorgeous set of stairs and we came up to this glass cube at the top of your roof. It’s sort of like a miniature Apple store. It took me a minute to realize, but I was seeing something I had never ever seen before. So what have you done with your roof that’s so unique?

Laura:

It’s nice that you say that we have a roof because frankly when I think about it, I say that the main thing which is strange in our building is that we don’t have a roof. So our roof is solar panels. Practically, we do not have any roof in between the solar panel and the roof. So from the industry, we are used to seeing that the panels are adds to the building. As you said before, we have roof plus the structure, plus also metal structure, plus the solar panel on top of it, and we added up a lot of additional work and additional materials and costs to fix the panel on the roof. This is what typically we are used to seeing.

Laura:

In our building, we do not have any inter-layer between the roof and the solar panel. The roof is made totally entirely in solar panels. They are made of four-six millimeter thick temperate solar glasses, and they are encapsulated with an insulating material. This insulating material, it’s enough to protect. So there is no real need for their insulation and for the materials.

Bill:

This is a breakthrough. Cool. I can’t overstate how I’m personally excited and I think the world needs to understand that there are people building buildings without roofs. They’re using solar panels that have the properties of roofs. And by combining them into a single component, you lower the cost of everything. Now, obviously, when you have this sort of specialty thing and these demonstration solar panels, you can’t possibly be creating very much electricity, right?

Laura:

Everybody thinks that solar panel doesn’t work, but that definitely is not true. What we are producing with our roof is more than 180 kilowatts, which is more than the electricity that actually our building and our production need. So we have a surplus that we can supply to the network. And this is really nice because with the extra capacity, we can also be able to decrease the fixed cost of the company.

Bill:

I feel like I’ve just warped into the future because this, it’s such an obvious idea. If I’m going to have people up 30 feet in the air building stuff to keep the rain and the moisture and the heat out of my building, why not just make it solar panels? And the fact that you have solar panels today that not only are providing capabilities, but they’re providing all the power… And my question earlier was clearly a layup because I knew the answer, but you’re providing all the power that you need for an industrial facility.

This is probably one of the most obvious ideas that no one’s ever heard of, that people just don’t intuitively believe, and yet you’re doing it. The thing I’m excited about is that because you’re making the machines that make these somewhat today specialized panels, you’re enabling the cost of these to get much more affordable.

Probably when your father was first thinking about this, the cost of even in the best of worlds was going to be much more expensive than traditional solar. But as California and Europe and companies like yours that automate this continue to do more and more, volumes go up, automation gets better, the prices are going to become so compelling that probably my grandchildren will laugh like, “Wait a minute, you just built a roof? Why would you not put solar into the roof?” And it’s going to be such an obvious idea, but they’re hopefully going to look at you and Ecoprogetti and say, “Those were the folks that were doing it early on.”

You guys have some amazing clients that are using this, not just functionally, but also beautifully. You have customers who are taking the machines that you make for them and they’re manufacturing high volumes of high quality aesthetic solar solutions. And there’s examples across Europe. You’ve sent me links. Tell me about some of those companies and the kind of buildings they’re building and maybe paint some pictures for us.

Laura:

What you say, it is really true. The BIPV customers, this is how we call them, this is an increasing portion of our solar panel typical customers along with all Europe, and it is increasing also in the US and Canada. How do they work? Typically, they integrate and they customize their PV panel for facades, for buildings, and for many other applications, for example, electric vehicles or they do have obligations for ships, for boats.

But typically the main point is that the panels have to be aesthetically nice. So this is the starting point for all these customers. We do have indeed customers that make tiles, red tiles, colored tiles, waved solar panels, flexible solar panels, which are embedded into structures.

The nice point is that they do not speak about PV panels, generally. They do not sell PV panels. They sell active facades. They sell active buildings, so they sell these kinds of active products. The building can have an active portion that produces electricity and another inactive portion which maybe is the shadowed one from the sun, which is not producing electricity.

Laura:

For example, some of our more famous BIPV customers in Europe are ISSOL, which is a Belgium company and Swiss company that was one of the inventors of the BIPV in our countries and in Europe. They started with this concept of the aesthetically nice panel and integrated into the house. So you don’t have to add on in the building items with structures and costs, but you just make the building together with the architect, which is fully integrated with the solar panels. Colored one, transparent solar panels-

Bill:

Transparent solar panels?

Laura:

Transparent as well, yeah, definitely.

Bill:

So like a window?

Laura:

This is very nice… Like windows. And this is used not only in the building industry but also in the greenhouses, on the farm, in hospitals, schools, wherever we need that the light goes through the windows.

Bill:

And you guys are basically working with companies like ISSOL to design machines that create high volumes, largely automatically create these beautiful panels. You also create the ones that don’t have solar cells in them and your machines are making both, I assume. That way, when the architect can design the facade or the roof or the windows, they can say “This is where the sun’s going to be shining. I’ll make these active and I’ll make the identical-looking ones not active, but I’m buying them all from ISSOL” or who you are helping make those panels.

Laura:

Yes.

Bill:

What other companies are you working with?

Laura:

So there are very many I could name, okay. ISSOL, as we said, EnergyGlass that is located in Milano, Intelligent Solar in Lithuania, MetaSolar, SunAge, Switzerland, Kyoto, Austria, Germany got plenty of sun glass, really, really many. All of them are doing some customized PV panel and really, really strange and particular applications. All of them, BIPV. This is how we call them.

Bill:

Great. Well, I feel like this is the beginning of something that will become a very widespread phenomenon. And again, as I said earlier, I can’t fathom that in 10 or 20 years, we won’t be building BIPV into everything.

What we do with all of our esteemed guests at the Freeing Energy Project is we ask them a couple of questions. We call them the lightning round questions and just get your quick reaction. I’m just going to run through each of our questions for you, starting with what do you think that people that don’t know the industry you’re in would find most surprising about it?

Laura:

Yes. So I believe one of the main surprises is definitely that the solar panel can not be only ugly, maybe as we are used to seeing them, but it can definitely be nice, integrated, good looking inside our houses and become a piece of our house.

Bill:

Second question. If you could wave a magic wand and see one thing changed as we transition to clean renewable energy, what would it be?

Laura:

One of our dreams is not to see anymore all these distribution channels and really ugly pillars and cables all around our green areas. What we will like to see is really that we shift into local production of electricity. You produce it while you use it. You don’t need to transport electricity. By transport electricity, we lose 30% of the real nominal power that we are transporting.

Bill:

All right, third question. What do you think will be the single most important change in how we generate, store, and distribute electricity in the next five years?

Laura:

Now I’m saying something that’s probably will get everybody crazy, but we do not see the reason to shift electricity from AC to DC and then DC, AC, and then again shifting it back to DC because this is where we use it. But this is something that it’s growing up as a question in the market. And depending on where we are using the electricity. Is it for house applications or domestic applications? Probably it’s not really needed.

Bill:

I’ve talked to many people that share that vision of a DC-centered world and I think the inverter companies we find because you still need a box to do the solar tracking, you still need a box to handle the voltage levels and charge the batteries properly.

Laura:

Sure.

Bill:

So I don’t think anyone’s harmed by this, but a DC world is certainly what Thomas Edison envisioned when he created the first grid in the United States in Manhattan, and it was only years later, I read about this a lot in the book, about why we switched over to AC. But that’s a great vision and it makes everything cheaper, better, faster, which is why I love it.

Bill:

Last question. A lot of people that listen to the Freeing Energy podcast are excited about the transition, but they don’t know what they can do about it. What would you tell somebody when they say, “Laura, what can I do to help get us to clean energy faster?”

Laura:

At an individual level, definitely we should not be scared about the renewable solutions which are coming. Solar panels are totally recyclable. They are not noisy. They are not difficult to handle. They are just add-on to our houses and they help everybody to make a little change in the world and produce a little bit of clean energy for our own use.

Bill:

I just launched a series called The Myths of Solar and it addresses 10 of the biggest myths, including everyone that you mentioned. I think this is one of the hurdles for us to get over in this industry, is to move past some of the noise and confusion around solar and, in fact, it’s a much better solution, not a perfect solution, but it’s a much better solution than some of its critics would say.

Bill:

Well, I have to tell you, Laura, I’ve been looking forward to talking to you today and this has been so fun. What Ecoprogetti is doing, what your customers are doing is inspiring. It is the future. I can’t see any other future other than inexpensive solar being used in components in buildings and lowering the costs and capturing more sun and being beautiful at the same time. There is no trade-off. And you guys are doing it today. It’s exciting to meet you. I hope that our audience is inspired by what you’re doing as I am. I think all of us will agree that this is a small glimpse into a very exciting future that we had today. So thank you so much for carving out some time to share your story and your vision with us, and thank you so much for what Ecoprogetti is doing to get the world of solar and the world of clean energy move forward much more quickly and beautifully.